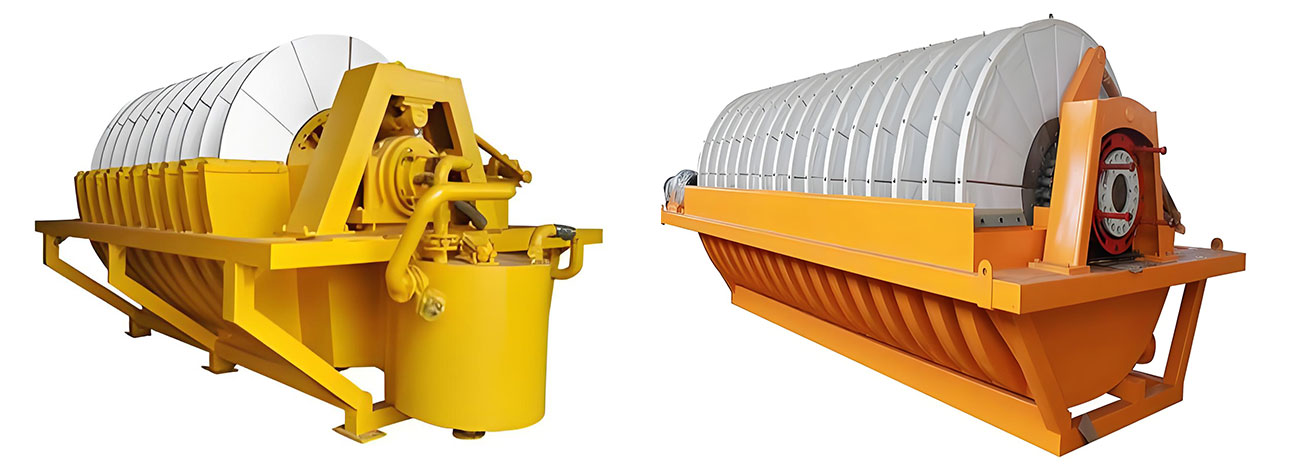

Ceramic disc filter

In industrial production, solid-liquid separation has always been an important checkpoint in many industries, ensuring both separation efficiency and environmental protection. Ceramic disc filter is improving efficiency and reducing consumption in fields such as mining and chemical industry with its unique structural design and excellent performance advantages.

What is a Ceramic disc filter machine?

The core idea of ceramic vacuum disc filter is very clear, using ceramic materials as the "core component" of filtration, coupled with vacuum adsorption technology, to separate solid particles in the liquid, and the efficiency is also relatively high. If opened, it is mainly divided into six parts: filter disc, ceramic filter plate, vacuum system, cleaning device, transmission mechanism, control system. Without any link, it cannot function.

The filter disk is the core component, with ceramic filter plates installed on its surface and fired using special processes. It also has very uniform small holes inside, with a diameter of about a few microns. It can not only intercept solid particles in the liquid, but also allow clean liquid to flow out smoothly through vacuum suction.

The filter disc slowly rotates along with the transmission system, first immersing itself in the tank containing the slurry, allowing the slurry to adhere to the ceramic plate, and then transferring to the vacuum adsorption zone. At this point, the vacuum system is activated, and the liquid is sucked away, leaving solid particles on the plate to form green tea cake. Then it goes to the cleaning zone, where residual impurities on the filter cake are washed away. Finally, it is transferred to the unloading zone, where the filter cake is scraped off and the liquid is already purified and recovered, ultimately achieving the process of solid-liquid separation.

The application advantages of Ceramic disc filter

In daily production, Ceramic disc filter is a very important equipment, mainly reflected in solid-liquid separation, resource recovery, and environmental compliance.

In terms of solid-liquid separation

It can effectively remove water from the slurry, separate solid particles to form a filter cake, with high efficiency and low moisture content in the filter cake. Taking the mining industry as an example, in the processing of minerals such as iron ore and copper ore, the use of ceramic disk filter to treat mineral slurry can reduce the moisture content of the filter cake by 10% -20%, effectively reducing energy consumption and costs in the drying process.

Resource recycling

Ceramic vacuum filter can intercept and recover useful components in industrial wastewater and solid-liquid, achieving the recycling of resources. For example, in chemical production, the ceramic vacuum disc filter can effectively recover catalysts, raw materials, etc. from waste liquid, which not only reduces production costs but also reduces resource waste.

Environmental compliance

This filter can effectively remove solid impurities and pollutants from industrial wastewater, ensuring that the treated water meets national discharge standards and reducing environmental pollution. At the same time, the separated solid filter cake can be further processed to achieve harmless disposal or resource utilization, which is in line with the current development concept of green environmental protection.

The difference between Ceramic disc filter and vacuum disc filter

The vacuum disc filter is a traditional solid-liquid separation equipment, and the Ceramic vacuum filter is a new equipment based on it. There are significant differences between these two devices in terms of filtering media, filtering performance, and application scope.

1. Filter media: Traditional vacuum disc filters mostly use filter cloth or mesh, which have inaccurate aperture accuracy and are prone to clogging, wear, frequent replacement, and high maintenance costs. The filter medium of Vacuum ceramic filter uses ceramic filter plates, which have uniform pore size, high accuracy, and are not afraid of high temperature, corrosion, or blockage. They have a long service life and greatly reduce maintenance costs.

2. Filtering performance: The Ceramic disc filter has uniform and fine aperture, high interception effect of solid particles, and good clarity of the filtered liquid. And ceramics have good breathability. Under vacuum suction, the slurry is filtered faster, and the resulting filter cake contains less moisture. On the other hand, due to the limitations of the filter cloth and screen, the filtration speed of the old equipment is slow, and there is still a lot of water in the filter cake. In addition, small solid particles may remain in the filtered liquid, making subsequent processing very troublesome.

3. Scope of use: Traditional vacuum disc filters are suitable for applications that do not require high precision, such as coal plants and power plants for preliminary filtration treatment. Due to the excellent performance of its filtering medium, ceramic disk filter have a wide range of applications and can be used in industries that require high filtration accuracy, strong slurry corrosiveness, and high temperatures, such as chemical plants, metallurgy, mining, environmental protection, and other industries that require fine filtration treatment.

Summary:

Ceramic disc filter not only differs from traditional equipment in terms of definition and structure, but also demonstrates significant advantages in terms of high efficiency, energy saving, and environmental protection in its performance. Compared to traditional vacuum disc filters, it has undergone comprehensive upgrades in terms of filter media, filtration performance, and usage range, which can achieve higher precision, higher efficiency, and more environmentally friendly requirements for solid-liquid separation in industrial production teams.

With the increasing emphasis on green production and resource recycling in the industrial field, Vacuum ceramic filter are widely used in industries such as mining, chemical, metallurgical, and environmental protection due to their unique advantages. We, Yinuo Machinery, will continue to upgrade our equipment and strive to provide industrial enterprises with more efficient, energy-saving, and environmentally friendly solid-liquid separation equipment, becoming a true helper for industry progress.