Product overview

Vacuum drum filter belongs to the continuous operation type filtration device, which can achieve solid-liquid separation with the help of the strong driving force formed by the negative vacuum pressure. In the operation of the equipment, the suspension is introduced into a specific processing area, under the action of vacuum negative pressure, the suspension of liquid can smoothly penetrate the filter media, such as filter cloth is one of the commonly used filter media. And solid particles will be intercepted by the filtration medium, and gradually accumulate to form filter cake.

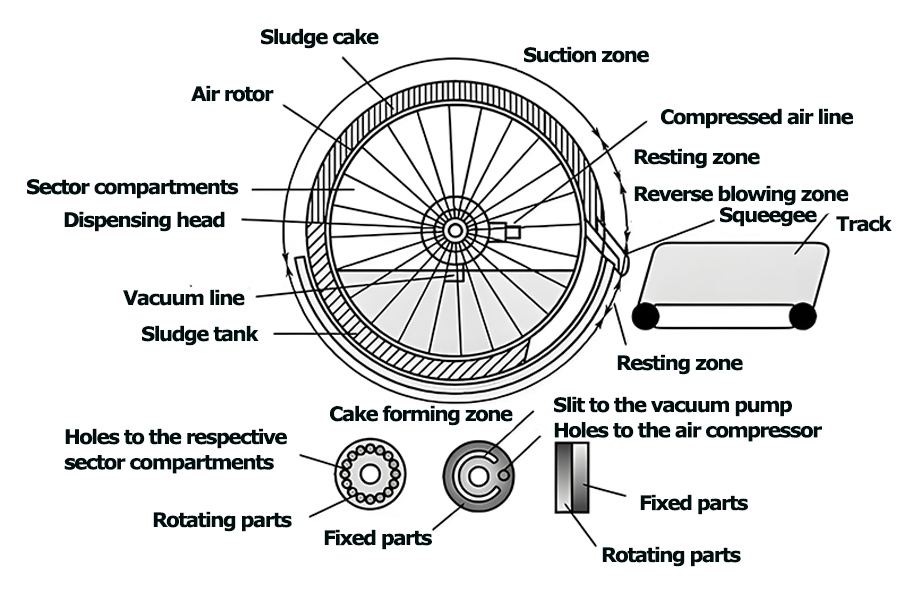

The core component of the rotary vacuum drum filter is a rotatable cylinder, also known as the rotary strand. The rotor is partially submerged in a slurry tank, covered with a filter cloth, and is internally connected to the vacuum system and compressed air system by means of a distributor head. As the rotor continues to rotate, a series of key processes such as filtration, washing, dewatering and cake removal are completed, ensuring that the entire filtration process is carried out in a more efficient and continuous manner.

Features of Rotary Vacuum Drum Filter

Continuous and efficient output:

It can operate continuously, realize uninterrupted production, shorten the production cycle significantly, reduce the loss of equipment start and stop time, significantly improve the production efficiency, and satisfy the demand of large-scale industrialized production on the output.

Depth and pure separation

Good washing effect of filter cake, uniform distribution of washing liquid to ensure full and thorough washing. Precise control of washing parameters can effectively remove impurities and soluble substances from the filter cake, realizing solid-liquid separation with high purity and guaranteeing product quality.

Accurate and flexible adaptation

Highly adjustable, the operator can accurately adjust the drum speed, vacuum and other key parameters according to the material characteristics, process requirements and production conditions, to adapt to complex working conditions and stabilize the filtration effect.

Compact and space-saving

Compact and reasonable structural design, scientific layout of components and integration of various functions. Compared with traditional equipment, it occupies a small area, which is conducive to optimizing the layout of the workshop, improving the utilization rate of space and reducing the site cost.

Vacuum Rotary Filter is widely used in chemical, mining, food, environmental protection and other industries, and it is more suitable to be used to deal with suspensions with high concentration and moderate granularity. The equipment through automated continuous operation, can produce stable output of high dryness of the cake, and filtration efficiency by the slurry nature of the fluctuations of the influence of less, is the industrial solid-liquid separation of one of the important equipment in the field.

Composition and structure of Drum vacuum filter

Air rotor

The air rotor is the core component of filtration, and the surface is covered with filtration medium. When rotating, it comes into contact with the sludge tank material, and vacuum adsorption allows the sludge to form a cake on the surface, realizing solid-liquid separation, which is the basic support and reaction place of the filtration process. 2. fan grid distribution head The fan grid distribution head precisely allocates the air and liquid paths.

Sector Grid Distributor

Sector Grid Distributor is used to precisely allocate the gas and liquid circuits. With the rotation of the rotating cylinder, it switches the fan-shaped lattice and connects with the vacuum and compressed air paths in an orderly manner, so that the various areas of the rotating cylinder can complete the filtration process in order, and it is the “scheduling center” of the equipment and technology.

Vacuum pipeline

Vacuum pipeline is connected to vacuum pump, creating a vacuum environment in the cake forming area, using negative pressure to adsorb sludge water, accelerating solid-liquid separation and cake forming, which is the key power channel to realize the function of vacuum filtration.

Sludge tank

The sludge tank is used for temporary storage of sludge to be treated, providing a stable space for the rotor to contact with materials. The rotor is partially immersed in the sludge to ensure a continuous and even supply of material, which is the “raw material contact area” affecting the feeding and filtering effect.

Scraper

The scraper is installed on the discharge side of the rotating drum. When the rotating drum turns to a specific position, the scraper scrapes off the molded filter cake and realizes the unloading and collection of the material, which is the key executing part of the material discharge after solid-liquid separation.

Compressed air line

Compressed air line in the blowback area into the compressed air, the rotor filter media blowback, clean up the residual particles in the pore space, to restore the permeability of the media, is to maintain filtration performance of the “clean path”.

Benefits of using Vacuum drum filters

In the entire operation process does not require frequent start and stop, effectively reducing the frequency of manual intervention, can seamlessly adapt to the rhythm and requirements of large estimation of industrialized production. In a long time, large quantities of production tasks, not only improve the production efficiency, but also significantly reduce labor costs, saving money for the enterprise.

The filter cake obtained after treatment by the equipment, the dehydration effect is relatively good, the water content can usually be controlled at a lower level of 10% -30%, at the same time, in the washing process, the equipment can ensure that the washing liquid is uniformly acted on the filter cake, so that the residual filtrate is greatly reduced, which a series of advantages effectively enhance the purity of the solid product, to ensure that product quality, stability and consistency.

It can easily cope with a variety of different types of suspension processing tasks, whether it is a high annual slurry, or a complex suspension containing a small amount of fiber, it can handle. Moreover, by flexibly adjusting the operating parameters of the equipment, such as the rotational speed of the drum, the vacuum generated by the vacuum system, etc., you can accurately meet the specific needs of solid-liquid separation in different scenarios, and truly realize a multi-purpose machine.

Compared with the pressurized filtration equipment, the vacuum system used in the equipment has obvious advantages in energy consumption. The vacuum system consumes relatively less energy in the operation process, which can effectively reduce the energy cost of the enterprise. In addition, the maintenance cost of the equipment is also lower, its structure is reasonably designed, the durability of the parts is stronger, reducing the trouble of frequent maintenance and replacement of parts, further saving the operating costs for the enterprise.

The equipment has a good closed, in the process of operation can effectively avoid the splash of slurry and the spread of odor. It effectively improves the operating environment of the workshop and reduces the chances of the staff coming into contact with harmful substances. At the same time, the neat and orderly workshop environment also helps to improve the image and management level of the enterprise.

Advantages of Drum Vacuum Filter

Compared with other filtration equipment, the core advantages of vacuum rotary filters are:

Comparison term | Vacuum drum filter | Plate and frame filter | Centrifugal filters |

Operating method | Continuous operation | Intermittent operation | Continuous/intermittent |

Degree of automation | High | Relatively low | Higher |

Cake dryness | Higher | High | High |

Treatment capacity | Large | Medium | Large |

Requirements for slurry stability | Lower | Higher (prone to clogging) | Higher (viscosity sensitive) |

Power consumption | Lower | Medium | High |

Drum vacuum filters have better cake washing effect, especially suitable for processes requiring multi-stage washing, and the equipment runs with low noise and is easy to maintain.

Vacuum drum filter manufacturer

Equipment selection and customization: according to the user's slurry nature and production needs, to provide personalized design solutions;

Installation and commissioning: a professional team to assist in the installation of equipment, debugging parameters, to ensure that the filtering effect is achieved;

Spare parts supply: the provision of filter cloths, distributor head seals, vacuum pump wearing parts, etc., to ensure that the equipment continues to run;

Technical support: regular return visits, fault repair, equipment registration Technical support: regular visits, fault maintenance, equipment registration.

Hot Tags: