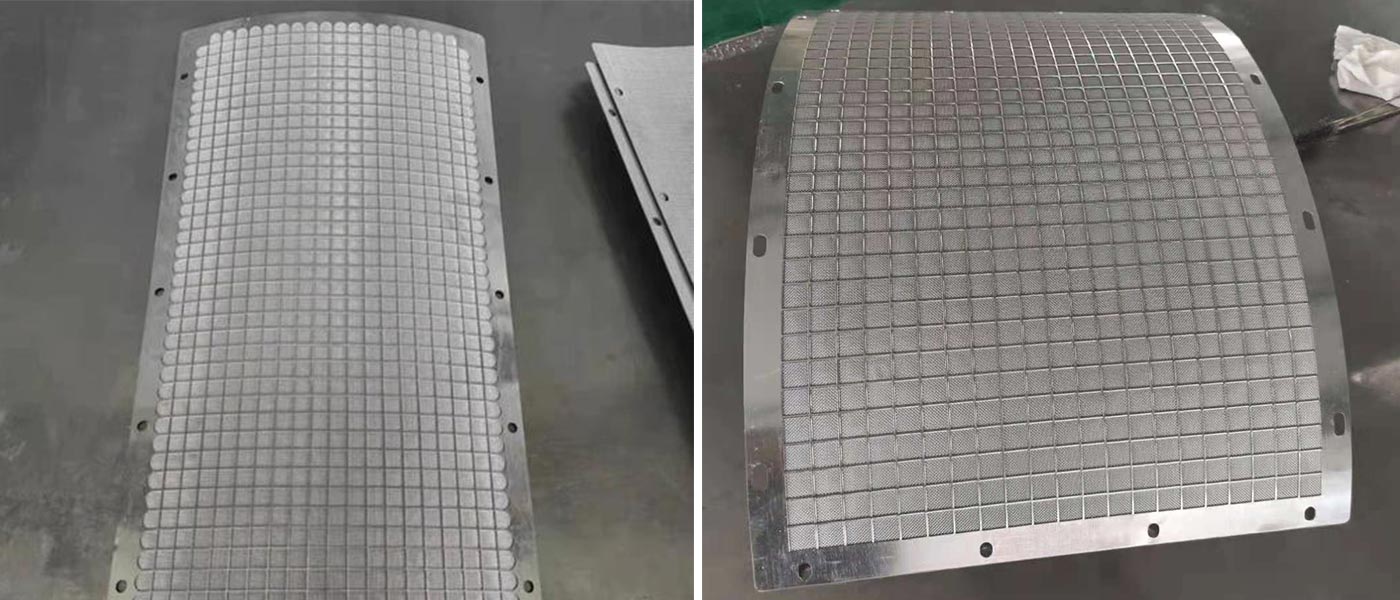

The filter screen of a rotary drum filter is an extremely critical component, serving the key functions of trapping contaminants and ensuring filtration precision. Proper maintenance of the filter screen not only guarantees stable equipment operation but also effectively extends the service life of the screen itself. Below is a detailed overview of the correct maintenance methods for the filter screen of a rotary drum vacuum filter.

1. Regularly clean the filter screen: As the equipment operates continuously, a considerable amount of contaminants will gradually accumulate on the surface of the filter screen. To avoid compromising filtration efficiency, a cleaning schedule should be established and implemented on time. Before cleaning, the power supply must be disconnected, and operations should only be performed after the equipment has completely cooled down. Gently remove the filter screen and rinse it thoroughly with clean water first; if contamination is severe, soak it in a neutral cleaning agent for approximately 10 minutes before cleaning. After cleaning, allow it to air-dry naturally and carefully inspect for damage or deformation—replace it promptly if any abnormalities are found.

2. Pay attention to the maintenance of the filter screen: During use, avoid excessive vibration or external impact on the filter screen to prevent damage to it. If fine cracks, damage, or hard-to-remove residues are found on the surface of the filter screen, it must be handled or replaced promptly. In addition, after removing the filter screen, you can gently scrub its surface with a soft-bristled brush to further remove deeply accumulated contaminants and prevent residual impurities from affecting filtration performance.

3. Prevent filter screen clogging: During operation, strictly control the feed material and prohibit large particle impurities or easily agglomerated substances from entering the filtration system to avoid clogging the filter screen. If abnormalities such as poor equipment exhaust or decreased vacuum degree are detected, immediately investigate whether they are caused by filter screen clogging, and unclog or clean the screen promptly.

4. Replace the filter screen regularly: After a period of use, the filter screen’s filtration performance will be compromised due to aging, damage, or clogging of the filter material. Therefore, it is recommended to replace the filter screen regularly in accordance with the recommended interval specified in the user manual. Meanwhile, when purchasing a replacement filter screen, ensure that its material matches the original equipment manufacturer (OEM) specifications, and balance filtration precision with durability.

5. Protect the filter screen properly during storage: If the equipment is shut down for an extended period, remove the filter screen and store it safely. Place the screen in a dry, well-ventilated area, away from direct sunlight or humid environments. During storage, wrap the filter screen in a plastic bag or dust cloth to prevent contamination from dust or debris.

Proper maintenance of the filter screen of a rotary drum filter has a significant impact on the machine’s normal operation and service life. It is essential to clean the filter screen regularly, pay attention to its maintenance, prevent clogging, and replace it at regular intervals. When storing the filter screen, care should also be taken to protect its integrity. By maintaining the filter screen correctly, the rotary drum filter can be ensured to operate effectively and stably, and its service life can be extended.