Product Description

The core component of a belt vacuum filter is a circular and movable filter belt, which is also the key medium for achieving filtration. Its working power is negative pressure, simply put, it relies on the suction force generated by vacuum to drive the filtration process.

During specific operation, it uses filter cloth as the core carrier for filtration. On the one hand, it relies on the weight of the material itself to naturally settle, and on the other hand, it cooperates with vacuum suction to complete solid-liquid separation. Unlike the vertical structure of some filtering devices, its filtering area is arranged horizontally, which makes the entire operation process smoother.

From practical applications, it can continuously complete a complete set of processes, first filtering and separating, then cleaning the formed filter cake, automatically removing the filter residue, and finally regenerating the filter cloth. The entire process does not require frequent manual intervention, achieving efficient continuous operation.

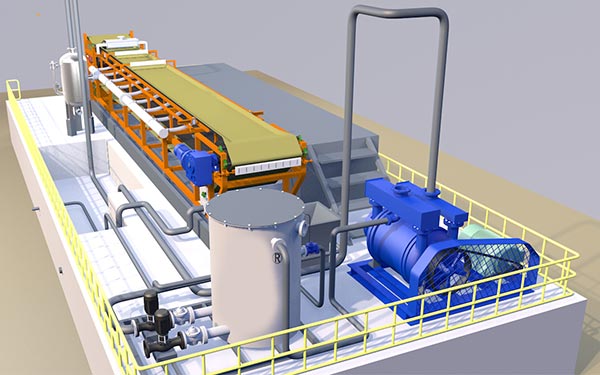

product structure

The core components of the belt vacuum filter include: motor, circular rubber belt, filter cloth, fabric feeder, vacuum chamber, steam water separator, support roller, and correction device. Among these components, the role of the annular rubber band is crucial, as it itself serves as a vacuum chamber. The filter cloth will be laid flat on the tape and run synchronously with the tape to ensure a smooth filtration process. And it is stated that it will be in close contact with the annular friction belt on the vacuum slide table, which can form a reliable water seal, prevent leakage in the vacuum environment, and ensure filtration efficiency.

Working Principle

Firstly, the slurry is evenly spread on the filter cloth through a fabric feeder, preparing for subsequent filtration. When the vacuum chamber is connected to the vacuum system, a vacuum filtration zone will be formed on the tape, and negative pressure will begin to take effect at this time.

The filtrate will pass through the filter cloth, then collect along the transverse grooves on the tape, and enter the vacuum chamber through the small holes on the tape; The solid particles in the slurry will be intercepted by the filter cloth, gradually forming a filter cake on the filter cloth. The liquid entering the vacuum chamber will be sent to the steam water separator for gas-liquid separation before being discharged.

As the circular rubber belt continues to move, the formed filter cake will enter the filter cake washing and drying areas in sequence, completing the cleaning and drying process. Afterwards, the filter cloth will separate from the tape, and when it reaches the position of the discharge roller, the filter cake will be smoothly unloaded.

After unloading the filter cake, the filter cloth will undergo specialized cleaning treatment to restore its filtering ability and achieve regeneration. It will then return to the filtering area and start a new filtering cycle, thus achieving continuous filtering operations.

Characteristics of Belt Vacuum Filter Machine

1. High degree of automation: equipped with PLC control system, supports remote control, reduces labor costs and operational errors;

2. Good filtration efficiency: After sedimentation, the material has large particles at the bottom and small particles at the top. The filter cake structure is relatively reasonable, and the filtrate permeability resistance is low, which can effectively achieve thin-layer rapid filtration with higher efficiency than traditional equipment;

3. Excellent washing performance: Supports multi-stage parallel or counter-current washing with separate collection of filtrate and washing solution, ensuring thorough and uniform cleaning to meet high-purity processing requirements.

4. Reasonable structural design: Fixed vacuum box design, tape and vacuum box form a running seal, tape is supported by rolling rollers to reduce running resistance, modular detachable frame for easy installation and maintenance;

5. Strong adaptability: able to handle materials of different concentrations, particle sizes, and viscosities. By adjusting parameters such as filter cake thickness, washing water volume, and washing stages, it can meet diverse production needs.

Solution for dehydration and product recycling

Dehydration:

The core of dehydration is achieved by vacuum suction. The vacuum environment will force the filtrate to pass through the filter cloth and enter the vacuum chamber, so that the solids and liquids can be separated.

When further reduction of filter cake moisture content is required, several practical methods are available:

First, install a hot air or steam drying system to accelerate moisture evaporation through elevated temperatures; Second, incorporate a compressed air blow-off device to remove excess moisture from the filter cake surface via airflow; Third, add a mechanical squeezing device to physically press out moisture.

In addition, coordinating the two key parameters of vacuum degree and filter cloth running speed in daily operations can also effectively optimize the dehydration effect and make the filter cake dryness more in line with the requirements.

Product Recovery Solutions:

During filtration, mother liquor and wash liquor can be collected separately to prevent waste from mixing.

For mother liquor containing valuable components, subsequent processes like evaporation or crystallization can extract and recover the dissolved solids. If the wash liquor is not highly contaminated, it can be recycled after simple treatment, thereby improving resource utilization and reducing production costs.

Hot Tags: