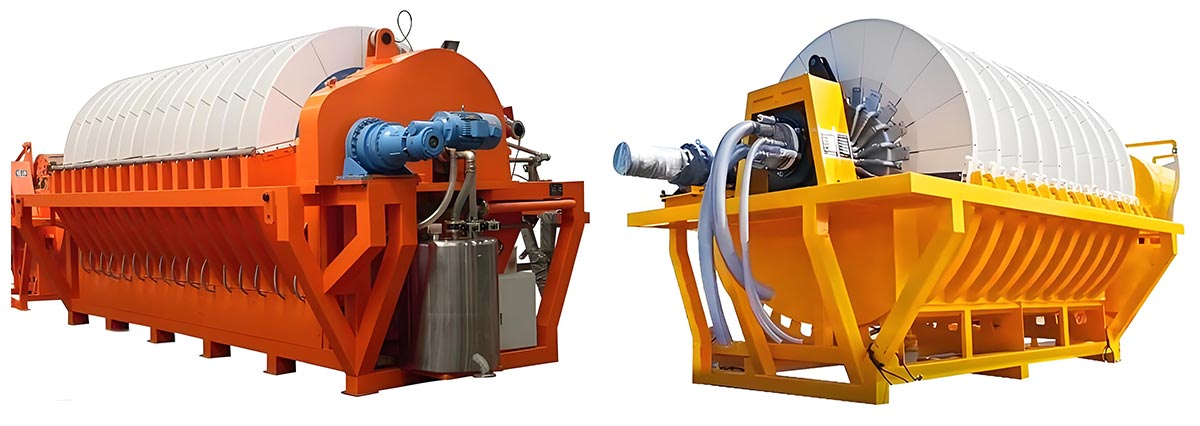

Ceramic disc filter

The ceramic disc filter utilizes vacuum as the filtration driving force to separate solids from liquids in slurry. This unit incorporates the strengths of comparable products while specifically optimizing overall performance and component reliability to address the characteristics of metal minerals: high density, rapid settling, and strong impact force on filter tubes from filtrate containing solid particles. This ensures excellent dewatering performance during solid-liquid separation of metal minerals. Field testing by users confirms that its primary technical specifications and performance meet advanced domestic and international standards.

Features

1. Fan-shaped filter plates feature uniformly distributed dewatering holes with optimal porosity and large-sized ribs. Constructed from high-strength engineering plastic, their service life is extended by 1-1.5 times. The filter liquid pipes offer a large filtration area, while the distribution head cavity maximizes suction efficiency and filter liquid discharge performance.

2. Wear-resistant nylon monofilament or double-layer composite filament filter cloth resists clogging, significantly improving dewatering efficiency and extending operational lifespan.

3. Centralized automatic lubrication via multi-point grease pump.

4. Automatic filter cloth cleaning system maintains optimal dewatering performance.

5. Horizontal forced-speed mixing with triple shaft-end sealing: rubber packing, graphite packing, and hydraulic pressure seal ensure zero slurry leakage.

6. Main drive employs stepless speed regulation (AC variable-speed motor or frequency converter) to adjust according to material concentration and flow rate, achieving ideal operational efficiency.

7. Each disc comprises 20 filter fan plates, enhancing filtration process control and ensuring uniform cake thickness.

8. Friction plates utilize specially formulated wear-resistant boron cast iron, combining rigidity and flexibility for superior sealing and extended service life.

9. Filter liquid pipes are made of high-strength, wear-resistant ceramic-composite steel pipes, increasing lifespan by over 10 times.

10. Elimination of upper/lower flanges at filter pipe-fan interfaces; mold-positioned direct welding reduces potential air leakage points by 90%.

11. Arc-shaped channels are injection-molded from engineering plastics in a single process, offering corrosion resistance and superior sealing.

Service Life of Ceramic Disc Filters:

The overall service life of ceramic disc filters typically exceeds 10 years, with specific duration influenced by core component wear, usage and maintenance practices, and application scenarios.

1. Overall Equipment Lifespan

Main Equipment: Under standardized operation and regular maintenance, the primary structure—typically constructed from high-strength steel or engineering plastics—exhibits strong corrosion and wear resistance. This ensures a stable service life of 10–15 years, potentially longer under certain operating conditions.

Lifespan of Core Wear Components:

Ceramic Filter Plates: 1.5–3 years; may shorten to one year under highly abrasive slurries.

Dispensing Head: 2-4 years; requires immediate adjustment or replacement after wear.

Agitator Impeller: 2-3 years; corrosion-resistant materials extend lifespan to 3-5 years.

2. Key Influencing Factors

Operating Conditions: Highly abrasive or strongly corrosive slurries accelerate wear.

Maintenance: Regular cleaning and lubrication prolong lifespan; inadequate maintenance reduces lifespan by 30%-50%.

Operation: Avoid overload operation and improper chemical usage.

Cleaning Methods for Disc ceramic filters

Routine Cleaning: Automatic Backwashing

This is the default cleaning method during operation, automatically controlled by PLC without manual intervention.

Principle: After each filtration cycle, backwash fluid is forced out in reverse through the ceramic filter plate via the distribution head.

Function: Removes impurities adhering to the aluminum plate surface and micro-pore inlets, maintaining the filter plate's basic filtration capacity to ensure continuous operation.

Periodic Deep Cleaning: Addressing Stubborn Blockages

When routine backwashing fails to restore filtration efficiency, deep cleaning is required—typically every 1-2 weeks, adjusted based on slurry impurity levels.

Ultrasonic Cleaning: Utilizes mixed-frequency ultrasonic vibration energy to dislodge stubborn fine particles trapped within micro-pores. Especially effective for viscous or fine-grained impurities, offering high cleaning efficiency without damaging filter plates.

Chemical Cleaning: For chemical blockages like oil residues or metal oxides, select appropriate chemical agents.

Cleaning Precautions

Avoid direct high-pressure water jet rinsing of ceramic filter plates to prevent microporous structure damage.

Thoroughly rinse residual chemicals after chemical cleaning to prevent subsequent contamination or corrosion of the filtrate.

Adjust cleaning frequency based on actual operating conditions. Shorten cycles when processing highly contaminated or viscous slurries.

Ceramic Disc Filters Manufacturer

Disc ceramic filter have become core equipment in scenarios such as concentrate and tailings dewatering in mining and metallurgy, raw material purification in the chemical industry, and sewage sludge treatment in environmental protection. Their high filtrate clarity and extended service life not only reduce enterprise production and operational costs but also assist industries in achieving green and efficient production. The realization and assurance of these performance capabilities rely on professional ceramic disc filter manufacturers.

Hot Tags: