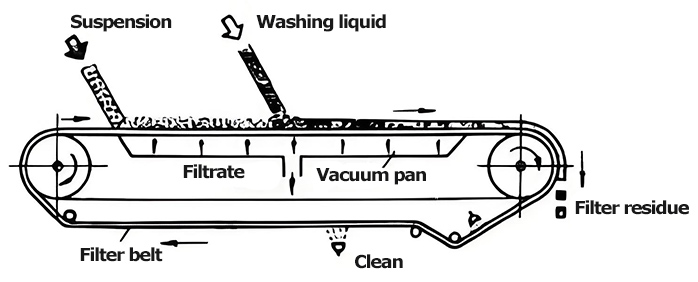

The vacuum belt filter is a highly efficient solid-liquid separation device that utilizes vacuum negative pressure as the driving force to achieve separation. Its filtration section is arranged along a horizontal length, enabling continuous automatic completion of a series of process operations including filtration, filter cake washing, cake discharge, and filter cloth regeneration. This equipment utilizes filter cloth as the filtration medium. A continuous rubber belt, driven by a motor through a reduction gear, moves synchronously with the filter cloth stretched across the frame. When the belt makes sliding contact with the vacuum chamber connected to the vacuum system, a vacuum filtration zone forms on the belt surface. At this point, the slurry is evenly distributed onto the filter cloth via a distributor. The filtrate permeates the filter cloth, collects in the transverse grooves on the belt, and then enters the vacuum chamber through small holes, while solid particles are retained to form the filter cake.

Product Advantages

High efficiency filtration

Adopting horizontal filter media surface feeding method, the large particles in the slurry can be quickly settled, and precipitated on the surface of the filter media in a very short time, to build up a primary filter media layer with high permeability, and the initial filtration effect is very outstanding.

High production capacity

It can continuously cut a series of process operations such as automatic bending and sinking filtration, filter cake washing, slag discharge and filter cloth regeneration, which greatly improves the production efficiency.

Good washing effect

The mother liquor and the washing liquor of the filter cake can realize segmented cell phone, supporting multi-stage flat flow or counter-flow washing mode, ensuring the washing process is even and thorough.

Low water content of the filter cake

With strong filtration performance, the resulting filter cake has low water content, which is very suitable for the subsequent processing requirements.

Flexible operation

The overall structure utilizes the modular design concept, which can be flexibly assembled according to the actual needs, greatly facilitating transportation and installation.

Low cost

High degree of automation, effectively reducing the manual operation, which in turn reduces the operating cost of the equipment.

Technical features:

· High degree of automation: continuous automation of the whole process of feeding, filtration, washing, sucking, unloading and filter cloth cleaning, and PLC program or DCS technology can be used to realize on-site or remote automatic control.

· Flexible process adjustment: parameters such as cake thickness, water absorption, number of countercurrent stages, vacuum degree, filter cloth, etc. can be adjusted according to demand, so as to achieve the best filtration effect.

· Deskewing device: the cylinder or airbag is used to push the deskewing mechanism to rotate and correct the deskewing, which automatically corrects the deviation of the filter cloth and ensures the normal operation.

· Tensioning device: Adjusting the tape tensioning progress with a screw to ensure sufficient friction and no deviation of the tape.

· High-efficiency cleaning: process water jet cleaning filter cloth and tape, with vacuum suction pipe sealing box, spray nozzle using high-quality products to ensure the cleaning effect.

The structure of a vacuum belt filter press

The components of a vacuum belt filter for gypsum are relatively intricate and can be divided into core functional components and auxiliary supporting components.

Core filtration and dewatering components

Filter belt: As the key filtration medium, the filter belt is responsible for carrying the material and completing the filtration and dewatering tasks. It is typically made of high-strength, wear-resistant woven materials, such as polyester or polypropylene.

Vacuum Chamber: Located below the filter belt, it uses negative pressure to adsorb materials from the filter belt's surface, serving as the key component for vacuum dewatering. It closely adheres to the filter belt to ensure effective vacuum performance.

Feed System: Includes a feed hopper and distributor, used to uniformly distribute the slurry across the belt, ensuring optimal utilization of the filtration area.

Dewatering section components: Divided into gravity dewatering zone, vacuum pre-dewatering zone, vacuum pressing dewatering zone, etc., based on the dewatering process. Different combinations of pressure and vacuum levels in each zone enhance dewatering efficiency.

Filter belt operation control components

Drive system: Comprising a motor, reducer, drive rollers, etc., it drives the filter belt to run continuously and can adjust the belt speed through speed control.

Tensioning device: Adjusts the filter belt tension via cylinders or lead screws to ensure the belt is tightly fitted to the pre-vacuum box, while preventing the belt from being too loose or too tight.

Alignment device: Includes sensors and pneumatic/electric adjustment mechanisms to monitor the filter belt position in real-time and make adjustments, preventing belt misalignment that could cause equipment malfunctions.

Auxiliary pre-installation components

Vacuum system: Comprised of a vacuum pump, vacuum piping, and a gas-liquid separator, it provides a stable vacuum source for the equipment.

Rinsing device: Includes spray pipes and nozzles, used to clean residual filter cake from the filter belt surface, preventing blockages and ensuring its permeability.

Discharge device: Typically a scraper or roller structure, it removes and discharges the dewatered filter cake from the filter belt.

Frame: A steel structure frame supporting all components, ensuring the overall stability of the equipment.

Control System: Comprised of a PLC, touchscreen, sensors, etc., enabling automatic adjustment of parameters such as filter belt speed, vacuum level, and rinsing pressure, as well as monitoring of equipment operation.

These components work together to complete the entire process of material feeding, filtration, dewatering, unloading, and filter belt regeneration, ensuring stable and efficient operation of the equipment.

Application areas

Vacuum belt filter for gypsum with excellent performance and various advantages, known as an indispensable key equipment for solid-liquid separation in many industrial fields, showing an extremely wide range of application prospects.

Metallurgical industry

The environment is harsh, high temperature and corrosive. The equipment has a sturdy structure, corrosion resistance, and can efficiently process slurry, accurately separate solid minerals and liquid fertilizers, provide high-quality raw materials for smelting, and improve production efficiency and quality.

01

Chemical industry

The materials are diverse, the reaction produces waste liquid containing solid impurities, this equipment can rely on the flexible adjustment of the material characteristics, to achieve high-precision solid-liquid separation, to protect the purity and quality of chemical products, to maintain production stability.

02

Paper industry

Looking for paper pulp production containing fibers, filler wastewater, vacuum belt filter press can be treated in depth, recovery of fibers and fillers, to achieve the use of resources in the utilization, reduce the impact of wastewater discharges, and help the paper industry environmentally friendly and efficient development.

03

Food and pharmaceutical industry

The equipment adopts high-quality materials, with perfect sealing and cleaning system, can be operated in an aseptic environment, to prevent material contamination, to protect product safety and quality stability, to meet regulatory requirements.

04

Environmental protection field

In the sewage treatment plant, the equipment can efficiently separate the suspended solids, sediment and other impurities in the sewage, so that the water quality meets the discharge standards and protects water resources. In tailings dry discharge, it fully removes the moisture of tailings, realizes dry stockpiling, and guarantees the safe production of mines.

05

Vacuum belt filter press price

The price of Vacuum belt filter press machines is influenced by various factors. Different processing capacities and filter belt widths can result in significant price differences. The level of configuration also has a significant impact on price, such as whether the machine is equipped with a flocculant addition system or an automatic control system, which can influence the final price.

In the manufacturing sector, there are currently many outstanding environmental equipment companies that can recommend suitable models based on different application scenarios, providing users with professional equipment and comprehensive services. YiNuo Machinery is a professional manufacturer of vacuum filter machines, offering high-quality products at reasonable prices. We welcome interested customers to send us an email at info@vacuumdrumfilters.com.

Hot Tags: