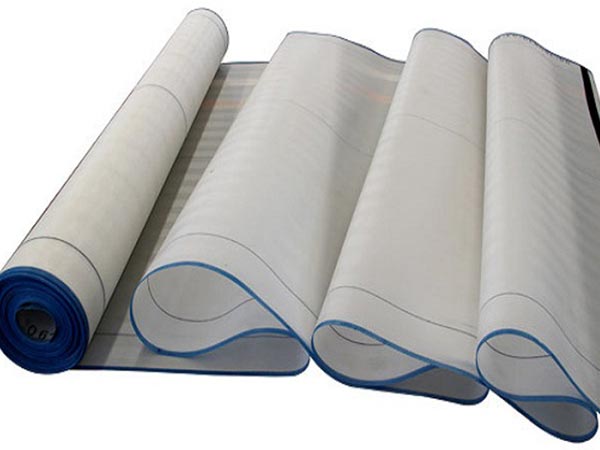

vacuum belt filter

The vacuum belt filter mainly operates through the cyclic movement of an annular filter belt, combined with the negative pressure environment formed by the vacuum box. This allows the slurry to quickly form a filter cake on the filter belt and complete dehydration. It features high automation, large processing capacity, and controllable filter cake moisture content, making it widely used in industrial scenarios such as mine tailings treatment, chemical sludge dehydration, and food processing.

As the core medium for the equipment to achieve solid-liquid separation, the unobstructed nature of the filter cloth's pores directly determines the filtration efficiency and equipment capacity. Filter cloth clogging is a common fault during equipment operation; in severe cases, it may require shutdown for maintenance. Below, we will explore the causes of filter cloth clogging and how to address it.

Causes of Filter Cloth Clogging in Vacuum Belt Filters

Improper Filter Cloth Selection: Inappropriate choices of filter cloth based on production processes or material specifications often lead to excessively high or low air permeability. This makes the filter cloth prone to dirt adhesion during operation, resulting in clogging.

Inadequate Timely Cleaning of Filter Cloth: After each production cycle of the filter, the filter cloth must be cleaned promptly to prevent filter residue from remaining on its surface. If the residue forms scale on the filter cloth, it will cause a rapid decline in the cloth’s dehydration performance and an increase in the moisture content of gypsum.

Equipment-Specific Issues of the Filter: These include insufficient vacuum pressure or overly viscous gypsum slurry. Overly viscous gypsum slurry tends to adhere to the filter cloth, leading to difficulties in cake detachment from the cloth.

Methods for Handling Filter Cloth Clogging in Vacuum Belt Filters

Clogging of the filter cloth in a vacuum belt filter can affect filtration performance and production efficiency. So, how should we address filter cloth clogging when it occurs?

1. Physical Cleaning

High-Pressure Water Washing

Use a high-pressure water gun to rinse the filter cloth, flushing away particles, impurities, and other substances that clog the cloth’s pores. During rinsing, adjust the water pressure and rinsing angle to ensure all parts of the filter cloth are thoroughly rinsed. Typically, the water pressure can be controlled at approximately 5–10 MPa.

Mechanical Vibration

A vibration device can be installed on the filter. Activate the vibration either during the filtration process or when the machine is shut down to make the filter cloth vibrate, thereby dislodging impurities clogging the cloth. Alternatively, manually tap the filter cloth gently to assist in removing clogs—take care to control the force to avoid damaging the filter cloth.

2. Chemical Cleaning

Acid Cleaning

If filter cloth clogging is caused by alkaline substances such as metal hydroxides, acid cleaning can be used. Common acids include hydrochloric acid and sulfuric acid. Prepare the acid into a solution with a specific concentration—for example, hydrochloric acid is generally 5%–10% concentration. Then soak the filter cloth in the acid solution for a period of time, usually 1–2 hours, and rinse it thoroughly with clean water afterward. Acid cleaning can effectively dissolve alkaline substances and restore the filter cloth’s filtration performance.

Alkali Cleaning

For filter cloth clogged by grease, organic matter, or similar substances, alkali cleaning is an effective method. Typically, alkaline solutions such as sodium hydroxide or sodium carbonate are used, with a concentration of approximately 5%–15%, and the soaking time is 2–3 hours. The alkaline solution can cause saponification of grease and other organic matter, allowing them to be removed. After soaking, the filter cloth must also be thoroughly rinsed with clean water.

Surfactant Cleaning

Leverage the emulsifying, dispersing, and solubilizing effects of surfactants to remove oil stains, impurities, and other contaminants from the filter cloth. Non-ionic or anionic surfactants can be selected and prepared into a 2%–5% solution. Soak the filter cloth in the solution or clean it via spraying—this effectively reduces the surface tension of the filter cloth, making it easier to remove clogs.

3. Adjusting Filtration Process Parameters

Reducing Filtration Pressure

If the filtration pressure is too high, particles are more likely to become embedded in the filter cloth pores, leading to clogging. Appropriately reducing the filtration pressure can make the filtration rate more uniform and minimize particle-induced clogging of the filter cloth. Generally, the pressure can be reduced by 10%–20% for observation.

Adjusting Feed Concentration

Excessively high feed concentration increases the filtration load on the filter cloth, making clogging more likely. Based on actual conditions, the feed concentration can be reduced by 10%–30% to ensure a smoother filtration process.

Adding Filtration Aids

Adding an appropriate amount of filtration aids (such as diatomaceous earth or activated carbon) to the feed can improve filtration performance. These aids form a precoat layer on the filter cloth surface, preventing particles from directly contacting the cloth and reducing the risk of clogging. The dosage is typically 0.5%–2% of the feed volume.

4. Replacing the Filter Cloth

Selecting the Appropriate Filter Cloth

If frequent filter cloth clogging is caused by mismatched material or pore size for the current filtered substance, it is necessary to replace it with a suitable one. For example, for materials with fine particles, a filter cloth with smaller pores and high filtration precision should be selected; for highly viscous materials, a filter cloth material with a smooth surface and low adsorption tendency is preferred.

Regular Replacement

Even with various cleaning and maintenance measures, filter cloths will gradually age, become damaged, and experience reduced filtration performance over time. Therefore, filter cloths should be replaced regularly based on their usage condition and the manufacturer’s recommendations. It is generally advised to inspect the filter cloth every 3–6 months and replace it if necessary.

Daily Prevention Recommendations

To reduce filter cloth clogging and insufficient vacuum pressure, daily equipment maintenance is required with operating parameters recorded in detail. Based on material properties and equipment operating conditions, a regular maintenance schedule should be developed, and wear parts should be promptly replaced to ensure the long-term stable operation of the system.

The above covers all the content regarding the cause analysis and handling methods of filter cloth clogging in vacuum belt filters. Through the detailed elaboration above, it is believed that readers have gained a comprehensive understanding of the core causes of filter cloth clogging and corresponding solutions. In the actual operation of vacuum belt filters, it is hoped that various clogging risk points can be accurately avoided, and the requirements for filter cloth selection, operation and maintenance can be standardized and implemented. Thereby, the equipment's operation and maintenance costs can be effectively reduced, the filtration efficiency and production continuity can be steadily improved, providing strong support for the smooth progress of industrial solid-liquid separation processes.