Mineral powder vacuum filter

The Mineral powder vacuum filter is a high-efficiency solid-liquid separation equipment specially designed for ore powder. It achieves rapid dehydration and continuous operation through the synergy of vacuum negative pressure and filter discs, and is suitable for various ore processing scenarios.

Working Principle

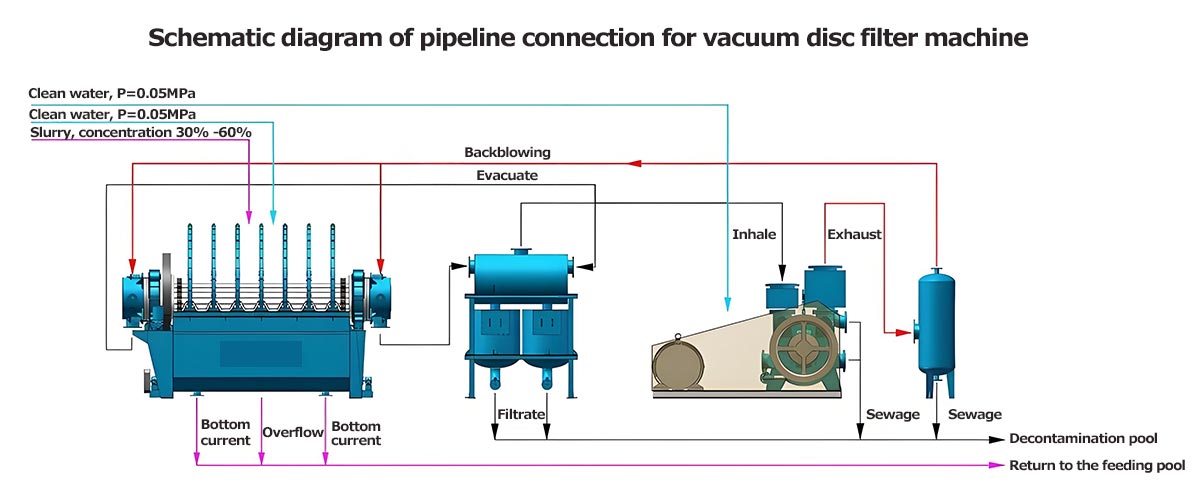

Adsorption and Cake Formation: Part of the filter disc is immersed in the slurry tank. By virtue of the pressure difference created by the vacuum pump, ore powder is adsorbed on the surface of the filter cloth to form a uniform filter cake.

Dehydration Enhancement: After the filter disc rotates out of the slurry, the moisture in the filter cake is further removed under the continuous action of vacuum, adapting to the characteristic that fine ore powder particles are difficult to dehydrate.

Discharging and Regeneration: The ore powder filter cake is discharged by inflating the filter cloth with reverse air flow and scraping it off with a scraper. Meanwhile, the filter cloth is automatically cleaned and regenerated to ensure continuous operation.

Product Features

Strong Adaptability to Fine Particles: The filter cloth can accurately capture ore powder of -200 mesh and finer, with a solid-phase recovery rate of over 99.7%.

Anti-Adhesion and Anti-Wear Design: The filter discs and tank body can be made of optional materials such as stainless steel and rubber lining, which can withstand the corrosiveness and abrasiveness of ore powder in mines.

Uniform and Stable Cake Formation: Each disc is composed of 20 fan-shaped plates. The filtration process is optimized according to the characteristics of ore powder, ensuring consistent filter cake thickness.

Uninterrupted Continuous Operation: It is suitable for the large-scale ore powder processing needs of mines, capable of operating 24 hours a day without interruption, with stable processing efficiency.

Product Applications

01

Metal Ore Powder

Used for dewatering of metal concentrates such as iron, copper, zinc, and lead. The moisture content of iron concentrate filter cake can be reduced to below 10%, meeting the requirements of smelting and transportation.

02

Non-Metal Ore Powder

Applied in dewatering of ore powders like phosphate rock, fluorite, and graphite. The moisture content of phosphate concentrate is stably maintained between 12% and 18%, which is suitable for downstream processes such as phosphate fertilizer production.

03

Production & Shipping

Suitable for dewatering of high-viscosity and fine-particle ore powders (e.g., bauxite, clay ore), solving the problem of low separation efficiency of traditional equipment.

04

Complate Work

Used for dewatering of mine tailings powder. It reduces the water storage pressure of tailings ponds, recovers water resources for recycling, and minimizes the loss of ore powder.

Hot Tags: