Precoat discharge rotary vacuum drum filter

The Precoat discharge rotary vacuum drum filter is the first type of high-efficiency automated solid-liquid separation equipment. Its core working principle is to form a porous precoat on the drum surface as the filtration medium, drive material filtration via vacuum negative pressure, and achieve continuous operation by integrating mechanical discharge. This equipment features high filtration precision, stable operation and convenient maintenance, and can effectively reduce production energy consumption and maintenance costs while improving overall production efficiency.

Features of Precoat discharge rotary vacuum drum filter

1.Structural Design:The drum is manufactured via integral welding or casting processes, with uniformly distributed filter holes on its surface and an anti-corrosive lining. The frame is made of steel structure, featuring high stability and suitability for heavy-duty operations in workshops.

2. Precoat System:It is equipped with a precoat mixing tank, metering pump and distributor, which can precisely control the thickness of the precoat and ensure consistent filtration performance.

3. Vacuum System:It adopts scraper or rope discharge mode, with adjustable scraper angle, enabling complete peeling of the filter cake without residue and effectively avoiding material loss.

4. Discharge Device:It adopts scraper or rope discharge mode, with adjustable scraper angle, realizing thorough stripping of the filter cake with no residue left, thus effectively preventing material waste.

5. Cleaning Function:A spray cleaning system is provided to perform countercurrent cleaning of the filter cake, which reduces the moisture content of the filter cake and effectively improves material recovery rate.

6. Safety Protection:It is equipped with overload protection, vacuum degree abnormal alarm, automatic liquid level control and other devices, complying with industrial safety standards.

7. Optional Materials:Material-contacting components such as the drum and shell can be made of 304 stainless steel, 316L stainless steel, titanium alloy, fluorine-lined material, etc., to adapt to different corrosive media.

Working Principle of Precoat discharge rotary vacuum drum filter

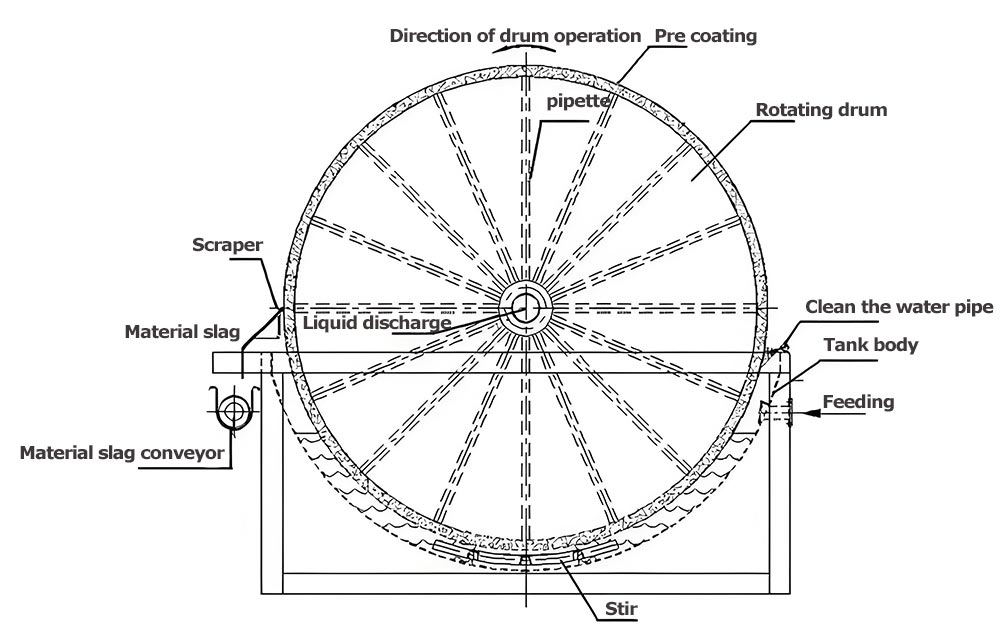

The filter uses a precoat as the high-precision filtration medium. Solid-liquid separation is driven by vacuum negative pressure, and a closed-loop process of regeneration-filtration-cleaning-discharging is achieved through the continuous rotation of the drum, enabling efficient treatment of fine-grained and difficult-to-filter materials.

The specific steps are as follows:

1. Precoat Formation:Precoat materials such as diatomite and perlite are mixed with water to form a suspension, which is adsorbed onto the drum surface under negative pressure to create a porous filtration layer with a thickness of 0.5–5 mm. This layer protects the drum and enhances filtration precision.

2. Negative Pressure Filtration:The drum rotates slowly and immerses into the material. Vacuum negative pressure drives the filtrate to pass through the precoat and the filter holes of the drum, while solid particles are trapped to form a filter cake.

3. Filter Cake Cleaning:After the drum rotates out of the material zone, the spray device sprays cleaning liquid. Under the action of negative pressure, residual valuable components in the filter cake are washed away and the moisture content is reduced.

4. Mechanical Discharging:A scraper or rope-type device is used to scrape off both the filter cake and the invalidated surface precoat layer, ensuring no residue remains on the drum surface.

5. Circulation Regeneration:The discharged drum re-adsorbs fresh precoat suspension to form a new filtration layer, initiating the next filtration cycle and enabling continuous operation.

Technical Parameters:

Technical Specifications | Specification Range |

Filtration area | 0.5-50 ㎡ |

drum diameter | 0.8-4.5 m |

Drum length | 1.0-6.0 m |

Drum speed | 0.1-5 r/min (infinitely adjustable) |

Degree of vacuum | -0.04~-0.09 MPa |

Operating temperature | ≤ 120 ℃ (conventional); ≤ 200 ℃ (customized for high temperature) |

Processing capacity | 5-500 m ³/h (depending on material characteristics) |

Moisture content of filter cake | ≤ 20% (depending on material characteristics) |

Pre coating thickness | 0.5-5 mm (adjustable) |

Power requirements | 380V/50Hz (three-phase) |

Material Options | 304/316Lstainlesssteel,titaniumalloy,rubberlining,fluorinelining |

Application Fields

Chemical Industry

Suitable for the filtration of organic/inorganic compounds, purification of fine chemical intermediates, and treatment of waste acids and waste alkalis.

Mining and Metallurgy

Widely used in the dewatering and filtration of mineral flotation tailings, high-efficiency separation of metal oxides, and advanced purification processes of rare earth elements.

Food Industry

Applicable to fruit juice clarification, beer filtration, edible oil refining, starch extract purification, and degreasing and clarification of dairy products.

Environmental Engineering

It performs excellently in the advanced treatment of industrial wastewater, and is also suitable for sludge dewatering as well as the recovery and utilization of gypsum—a by-product of flue gas desulfurization.

Pharmaceutical and Biochemical Engineering

Supports the high-purity filtration of pharmaceutical intermediates, clarification of fermentation broths, and purification of bioactive substances such as antibiotics.

New Materials Industry

Suitable for the precision filtration of lithium battery materials and the refinement of raw materials such as ceramic powder.

Performance Advantage Comparison Between Precoat discharge rotary vacuum drum filter and Conventional Vacuum Drum Filter:

performance metrics | Pre coated discharge vacuum drum filter | Ordinary vacuum drum filter machine |

Quality of filtrate | Extremely high clarity, approaching 'zero turbidity' | General clarity |

Filter cloth lifespan | Significant extension (due to pre coating protection) | Shorter (direct contact with particles) |

Filter stability | Excellent (Pre coating continuously updated) | Generally (filter cloth is prone to clogging) |

Applicable material scope | More extensive (especially fine materials) | Narrower (mainly suitable for conventional materials) |

Operation cycle | Long (reduce downtime and fabric replacement frequency) | Short (requires regular cleaning or replacement of filter cloth) |

Equipment complexity | Higher (increase pre coating system) | Lower |

operating cost | Slightly higher (requires consumption of filter aid) | Low(noadditionalfilteraidconsumption) |

When to Use a Precoat discharge rotary vacuum drum filter?

When the feed contains fine particles (1–50 μm), conventional filter cloth fails to meet the required filtration precision, and a high-clarity filtrate is demanded.

When the feed has high viscosity (>500 mPa·s), leading to frequent clogging and low processing efficiency in standard filtration equipment.

When continuous operation is required during production, with high automation and minimal manual intervention.

When the feed is corrosive or high-temperature, requiring special material configurations for compatibility.

When there are strict requirements for filter cake moisture content and material recovery rate.

When applied in large-scale production scenarios that demand stable throughput and controlled maintenance costs.

Hot Tags: