Product Introduction

Rotary disc filter, also known as vacuum disc filter, is a solid-liquid separation equipment powered by vacuum.

The Rotating disc filter is a filter disc composed of multiple independent fan-shaped filter plates, each of which is equipped with high-strength cotton polyester monofilament woven filter cloth. The rapid adsorption of slurry particles into cakes is achieved through the pressure difference effect generated by vacuum negative pressure. The equipment manufacturing adopts precision mold positioning welding technology, effectively reducing welding porosity. Combined with variable speed drive stirring device and pulse back blowing discharge system, a complete solid-liquid separation solution is formed.

Characteristics of Rotary disc filter

Filter plate upgrade

High strength engineering plastic fan-shaped filter plate, with a lifespan increase of 1-1.5 times and higher dehydration efficiency.

Filtrate optimization

The large diameter ceramic composite filtrate tube improves the pumping efficiency by 30%.

Long service life of filter cloth

The double-layer cotton wheel filter cloth has a cake removal rate of 98%, and with automatic cleaning, the replacement cycle is extended by 2 times.

Good dehydration effect

High pressure nozzle cleaning and dynamic pressure adjustment can maintain a good dehydration effect.

Sealing upgrade

Triple sealing with zero leakage, doubling the lifespan of the mixing shaft.

Adjustable transmission

The main transmission is infinitely variable, which can be adjusted according to the concentration and flow rate of the material to achieve the desired working effect.

Easy unloading

Each plate consists of 20 fan-shaped plates, with a residual unloading rate of less than 0.1%.

Durable sealing

The friction plate is made of special wear-resistant boron cast iron, which combines rigidity and flexibility for good sealing, and has a service life of more than ten years.

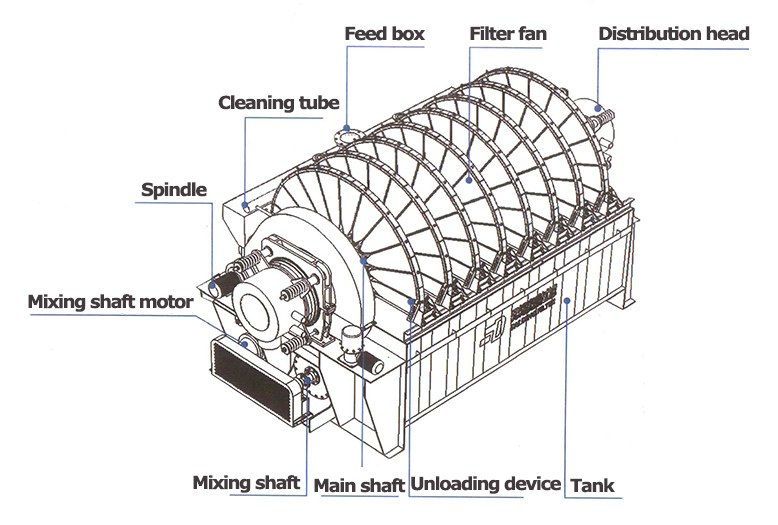

Structure of rotary disc filter

The rotary disk filter is primarily designed around the core principles of “negative pressure-driven filtration combined with continuous operation,” with all components working in tandem to achieve solid-liquid separation. The key structural components are as follows:

Disc

Composed of multiple independent discs connected via seals to form a seamless circular disc. Motor power is transmitted through a reducer and open gear drive to drive the disc to rotate at a stable and uniform speed, laying the foundation for continuous filtration.

Filter cloth

Covering the fan-shaped surface, it forms an independent filter chamber with the fan-shaped plates. Made from wear-resistant and corrosion-resistant materials, it ensures stable filtration, reduces damage and material leakage, and extends service life.

Vacuum system

Comprising a vacuum pump, vacuum pipes, and control valves, it creates a stable negative pressure by extracting air from the filter chamber. Under the influence of the negative pressure difference, it drives the liquid through the filter cloth, providing the energy for efficient filtration.

Distribution Head

Serves as the connection between the vacuum system and the filter chamber. It features precise channels and rotates synchronously with the rotating disc, evenly distributing negative pressure across all filter chambers to prevent uneven pressure from affecting filtration efficiency.

Agitator

Installed inside the filter chamber, it uses rotational or reciprocating motion to continuously stir the slurry, preventing solid particles from settling and blocking the filter cloth. This ensures uniform slurry concentration and maintains stable filtration.

Discharge Device

Located below the rotating disc, it uses air blowing or mechanical vibration to discharge the material. The filter cake falls into the discharge槽, facilitating subsequent centralized processing and achieving a closed-loop operation.

Working process

When the filter disk rotates clockwise, the negative pressure generated by the vacuum pump in the adsorption zone of the filter chamber creates a pressure difference between the slurry on both sides of the filter medium, promoting solid particles to adsorb onto the filter cloth and gradually form a filter cake. At the same time, the stirring device continues to operate, effectively avoiding the settling of solid particles in the slurry. After the filter cake rotates away from the page with the filter disc, it is further dehydrated under the suction effect of the vacuum system. The filtrate then passes through the filter cloth and filtrate tube in sequence, and is finally discharged through the distribution head. When arriving at the unloading area, the filter cake automatically falls off through the anti blowing device and falls into the discharge chute, and the entire operation process continues in this cycle.

Product Applications

1. Food Industry: As a critical separation device, it is used for starch purification, syrup clarification, dairy product impurity removal, and beverage filtration. Addressing the food industry's stringent requirements for hygiene and efficiency, it ensures product purity while minimizing production downtime and reducing operational costs, thereby supporting large-scale processing.

2. Chemical Industry: Suitable for applications such as mineral slurry dewatering, paint refinement, dye purification, and separation of pharmaceutical intermediates. Addressing the corrosive and high-viscosity characteristics of chemical materials, it achieves precise separation through superior filtration performance, while being low-pollution and easy to clean, meeting production purity and safety requirements.

3. Metallurgy Industry: Used for solid-liquid separation in mineral processing and tailings treatment, it efficiently separates solids and water from slurry, enhancing metal recovery rates and resource utilization while reducing tailings wastewater discharge and pollution, aligning with green production objectives.

4. Other Fields: It demonstrates significant application potential in environmental protection, energy, construction materials, and other industries, aiding in emissions reduction, efficiency improvement, and product quality assurance, with application scenarios continuously expanding.

After sales service of rotating disc filter manufacturers

The equipment manufacturer usually provides users with a certain period of warranty support. During the warranty period, if the equipment malfunctions due to non-human factors, the manufacturer will provide free repair or component replacement services. At the same time, the manufacturer will provide professional installation and debugging guidance to ensure the smooth operation of the equipment. In addition, the manufacturer has set up a 24-hour technical consultation hotline to answer technical questions for users during equipment use at any time, and provide remote troubleshooting guidance. Manufacturers will also regularly visit users, track the usage status of equipment, provide targeted maintenance suggestions in a timely manner, and ensure the long-term stable operation of equipment.

Hot Tags: