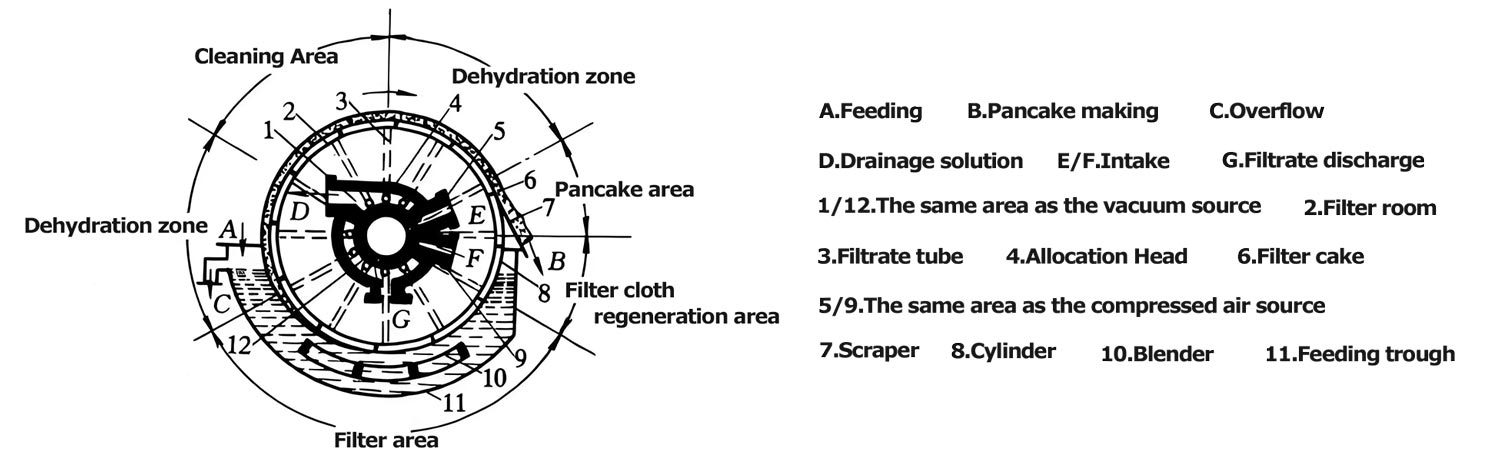

A vacuum rotary filter is an industrial device that achieves continuous solid-liquid separation using vacuum suction and a rotating drum. Its core component is a slowly rotating, hollow drum covered with filter cloth on its surface. Through the suction generated by internal vacuum pumping, the liquid in the suspension is drawn into the drum, while solid particles are retained to form a filter cake—enabling continuous filtration, dehydration, and discharge. It is widely used in industries such as chemical engineering, mining, and environmental protection.

Specifications

Model | Filter area (㎡) | Drum diameter (m) | Immersion angle (°) | Drum speed (r/min) | Host power (kW) | Weight (kg) | Sizing (mm) |

G2/1.0 | 2 | 1 | 120 | 0.13~2 | 0.37 | 1520 | 1600x1800x1500 |

G5/1.6 | 5 | 1.6 | 120 | 0.13~2 | 0.55 | 2500 | 2200x2600x2100 |

G10/2.0 | 10 | 2 | 140 | 0.13~0.79 | 1.5 | 4160 | 3380x3000x2170 |

G15/2.5 | 15 | 2.5 | 140 | 0.13~0.79 | 1.5 | 5300 | 3860x3100x2750 |

G20/2.5 | 20 | 2.5 | 140 | 0.13~0.79 | 1.5 | 6320 | 4460x310x2750 |

Working Principle of the Vacuum Rotary Filter

The working principle of a vacuum rotary drum filter lies in the collaborative operation of its rotating drum and internal vacuum system to achieve continuous solid-liquid separation.

The drum is partially submerged in the suspension to be treated. The internal vacuum system creates negative pressure, which draws the liquid into the drum for discharge. Simultaneously, solid particles are adsorbed onto the filter medium on the drum surface, forming a filter cake.

As the drum rotates continuously, the filter cake passes through a washing zone, a drying zone, and finally reaches a discharge zone, where the discharge process is completed. The filter medium then re-submerges (into the suspension) to start the next cycle, enabling the continuous operation of the entire solid-liquid separation process.

Features of the Vacuum Rotary Filter

1.Efficient and Automated Operation

By rotating the drum, the filter completes four key processes—filtration, washing, drying, and discharge—enabling continuous production. Parameters such as rotation speed and vacuum degree can be adjusted automatically, eliminating the need for intermittent manual operation and reducing labor costs.

2.Stable Separation Performance

The continuous action of vacuum negative pressure not only ensures fast separation speed but also enables deep dehydration, resulting in a low moisture content of the filter cake. The separation efficiency is less affected by fluctuations in material concentration, ensuring stable and controllable performance.

3.Wide Material Adaptability

After replacing the filter cloth and adjusting parameters like rotation speed and vacuum degree, the filter can be adapted to various materials, including granular, viscous, and crystalline ones. It is applicable across fields such as chemical engineering, food processing, and mining.

4.Compact Structure and Easy Maintenance

Integrating multiple functions into one unit, the filter occupies a small footprint. Its core components are easy to assemble and disassemble. Daily maintenance mainly involves cleaning the filter cloth and replacing wearing parts, making the operation simple.

Rotary Vacuum Filter Video

Hot Tags: