The Horizontal vacuum belt filter is a new type of highly efficient solid-liquid separation equipment. It features high filtration efficiency, low energy consumption, and excellent washing performance, making it widely used in industries such as chemical engineering, metallurgy, mining, food processing, and pharmaceuticals.

The Horizontal vacuum belt filter is a continuously operating solid-liquid separation device whose core principle combines vacuum filtration with mechanical conveying. During operation, the filter cloth undergoes continuous cyclic motion driven by the drive rollers, while the suspension is evenly distributed across the filter cloth surface via the feed mechanism. A vacuum chamber, fixed beneath the filter belt and connected to the vacuum system, creates a negative pressure zone on the filter cloth surface. Under this vacuum, liquid permeates the cloth into the vacuum chamber while solid particles are retained on the cloth to form a filter cake. As the belt advances, the filter cake undergoes formation, washing, and dewatering stages before being scraped off at the discharge end. Throughout the process, the filter cloth is regenerated via a cleaning device and returned to the feed end to commence a new cycle. This dynamic filtration mechanism enables continuous and automated processing, significantly enhancing separation efficiency.

Structure of Vacuum Belt Filter

Drive Unit

Consists of a variable frequency motor, reducer, drive roller, belt, filter cloth, etc., driving the operation of the belt and filter cloth.

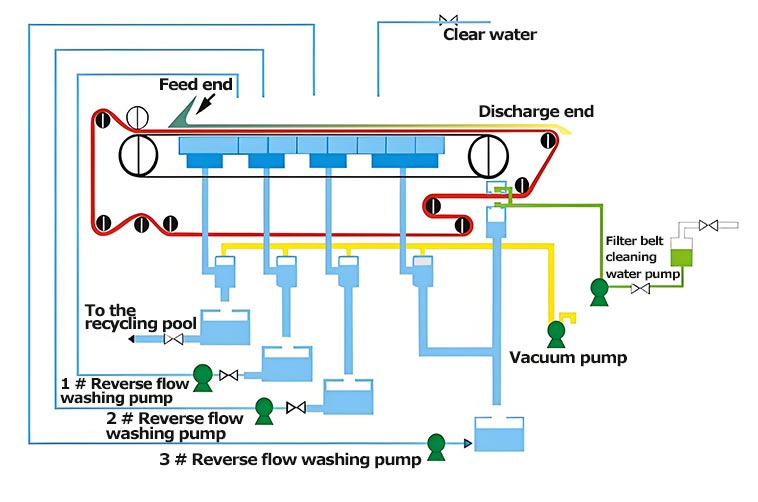

Vacuum System

Includes vacuum pump, vacuum separator tank, vacuum chamber, friction belt, etc. The friction belt forms a dynamic seal between the vacuum chamber and belt, enabling vacuum filtration.

Filtration and Washing System

Comprising a feed pump, distributor, wash pump, wash tank, filter cloth, and rubber belt, this system performs material filtration, washing, and dewatering.

Web Guiding System

Includes web guide proximity switches, guide rollers, air bags, and solenoid valves to correct filter cloth misalignment and ensure stable equipment operation.

Performance Features:

High Filtration Efficiency: When material is fed onto the horizontal filtration surface, larger particles settle first, forming a permeable primary filter layer. This layer effectively reduces filter cloth clogging, significantly lowering filtration resistance. This results in highly clarified filtrate, meeting fine filtration requirements.

Excellent Washing Effect: The equipment produces uniformly thick filter cakes with balanced distribution of wash liquid across the cake surface. Flexible multi-stage co-current or counter-current washing methods can be employed during operation, enhancing washing efficiency while enabling separate recovery of mother liquor and wash liquid for subsequent resource utilization or treatment.

Flexible and Convenient Control: To optimize solid-liquid separation, parameters such as filter belt speed, cake thickness, and the lengths of filtration, washing, and dewatering sections can be adjusted based on material characteristics, ensuring the separation process achieves ideal conditions.

High Automation Level: The equipment integrates multiple automated functions, enabling fully automatic continuous operation from feeding, filtration, and washing to cake discharge and filter cloth cleaning without manual intervention. This not only reduces labor costs but also eliminates human operational errors, ensuring stable performance.

Excellent Corrosion Resistance: The filter belt utilizes specialized corrosion-resistant materials. Core components like the vacuum chamber and gas-liquid separator can be constructed from corrosion-resistant materials such as stainless steel or titanium based on material properties. It reliably handles acidic, alkaline, or other corrosive materials.

Low Energy Consumption: The filter belt operates at a slow speed, and the main shaft rotation remains within a low-energy consumption range. Combined with the precision sealing design between the vacuum chamber and filter belt, which maintains stable vacuum levels, the required vacuum pump power is significantly reduced. This results in substantial long-term energy cost savings.

Product image

Model Specifications

Specification and model | Belt width | Filter area | Effective filtering length | Processing capacity | Adaptation scenario |

B1000-5 | 1000 | 5 | 5 | 1-5 | Small scale chemical and food processing (such as starch and juice clarification) |

B1200-8 | 1200 | 8 | 6.7 | 3-8 | Medium sized environmental protection (such as municipal sludge dewatering), mining tailings treatment |

B1500-15 | 1500 | 15 | 10 | 8-15 | Large scale mines (such as copper and iron tailings dry discharge), chemical crystallization material filtration |

B2000-25 | 2000 | 25 | 12.5 | 15-25 | Large scale metallurgy (such as steel pickling sludge), power plant desulfurization gypsum treatment |

B2500-40 | 2500 | 40 | 16 | 25-40 | Large scale chemical industry (suchas PVC resin filtration ), building materials (dehydration of gypsum board raw materials) |

Separation Performance

The separation efficiency of Horizontal vacuum belt filter directly impacts subsequent costs and operational efficiency. When evaluating the two key metrics—“cake moisture content” and “filtrate clarity”—standards must be set based on specific end-use requirements:

Cake Moisture Content: Align with Post-Processing Demands

The moisture level of the filter cake determines disposal costs. Industry-specific requirements for moisture content vary significantly:

1. If filter cake requires incineration, moisture content must be controlled below 60% (excessive moisture increases fuel additive usage and raises incineration costs);

2. If filter cake requires landfill disposal, some regions mandate moisture content below 70% (to prevent leachate from contaminating soil);

3. If filter cake requires resource recovery, moisture content must be reduced to below 30% (to ensure combustion efficiency).

Buyers must clearly define their moisture content threshold for filter cake disposal and require suppliers to provide moisture content test reports for similar materials. On-site trial runs are recommended: process actual production material for 1-2 hours, sample the filter cake for moisture content testing, and verify results align with requirements. Note: Some suppliers may reduce moisture content by “extending filtration time,” which decreases throughput. Carefully balance “moisture content” and “throughput” to avoid sacrificing one for the other.

Hot Tags: