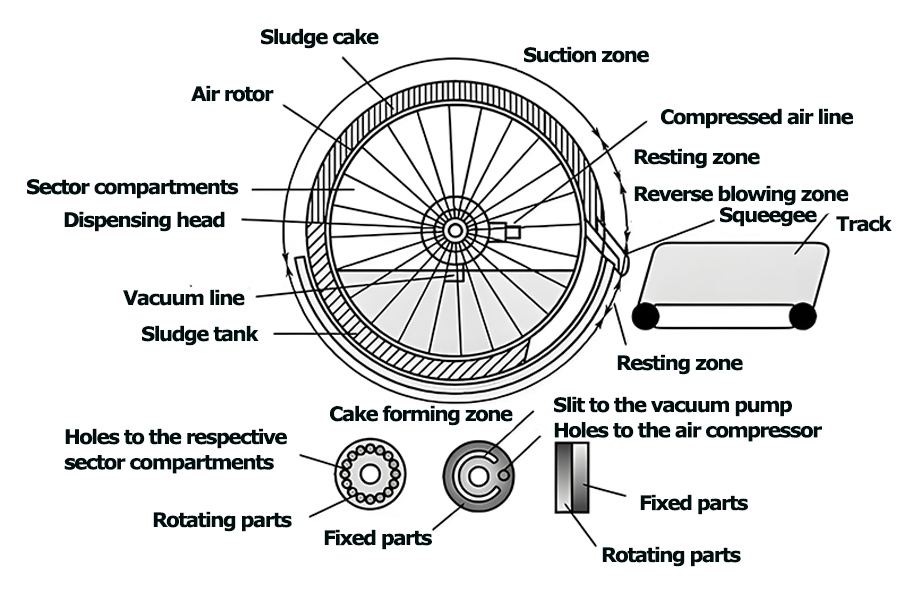

The Rotating vacuum filter is a continuous solid-liquid separation device particularly suited for suspensions with high throughput and relatively uniform solid particles. Its core principle utilizes vacuum pressure as the driving force to push the liquid phase through the filter medium while retaining solid particles to form a filter cake. Through a continuously rotating filter drum, it performs filtration, washing, drying, and cake discharge processes, enabling automated continuous production.

Core Workflow

Filtration Zone: The filter drum is immersed in the suspension tank. Internal vacuum draws liquid through the filter cloth into the drum, while solid particles form a uniform filter cake on the cloth surface.

Washing Zone: The filter drum rotates beneath the washing spray system. Clean water or washing solution is sprayed onto the filter cake to remove soluble impurities. The washing solution is also drawn into the filter drum by vacuum.

Dewatering Zone: After leaving the washing zone, the filter cake continues through the vacuum zone. Residual liquid is further extracted to reduce the cake's moisture content.

Discharge Zone: The filter drum rotates into the vacuum-free zone. A scraper removes the dried filter cake from the filter cloth, completing the discharge process.

Regeneration Zone: Some models feature a filter cloth cleaning device after discharge. This removes fine particles adhering to the filter cloth, restoring its filtration performance and ensuring stable operation in the next cycle.

Core Performance Advantages:

When selecting equipment, buyers are particularly concerned about factors such as efficiency, filter cake moisture content, and energy consumption. Let's take a closer look at these aspects below.

Efficient operation: The Rotating vacuum filter can operate continuously 24 hours a day without the need for frequent shutdown and unloading like the plate and frame filter press, making it more suitable for large-scale production scenarios.

Low Filter Cake Moisture Content: The optimized vacuum system achieves filter cake moisture levels as low as 15%-30%, reducing subsequent drying energy consumption by over 40% and significantly lowering production costs.

High Adaptability: Customizable filter cloth materials, drum speeds, and vacuum levels accommodate diverse applications—from fine-particle suspensions to high-viscosity materials—based on material properties.

High Automation: Features automatic feeding, washing, unloading, and filter cloth cleaning. Requires only 1-2 operators for routine inspections, minimizing manual labor while eliminating human error and safety risks.

Energy-Efficient and Eco-Friendly: Utilizes high-efficiency vacuum pumps that reduce energy consumption by 20%-30% compared to traditional models. Recovers and reuses mother liquor and washing solutions generated during filtration, minimizing wastewater discharge and complying with national environmental policies.

Technical Specifications:

Technical Specifications | Conventional scope | Customized instructions |

Drum diameter | 0.8-3.0m | The larger the diameter, the larger the filtration area, and the higher the processing capacity |

Drum length | 1.0-6.0m | The length and diameter together determine the filtration area (area=π x diameter x length) |

Filter area | 2-57㎡ | The processing capacity is positively correlated with the filtration area, with a conventional processing capacity of 5-100m ³/h |

Drum speed | 0.1-5r/min | Variable frequency adjustment, optimized speed according to material characteristics (fine particles should be slow, coarse particles should be fast) |

Vacuum degree | -0.06~-0.095MPa | Can be adjusted according to the thickness and moisture content requirements of the filter cake |

Filter cake thickness | 5-50mm | Coordinated control of rotational speed and vacuum degree |

Equipment material | 304 stainless steel/316L stainless steel/Q235 carbon steel | Choose 316L for corrosive materials and 304 or Q235 for ordinary materials |

Vacuum pump type | Water ring vacuum pump/Roots vacuum pump | Recommended for high-capacity scenarios: Roots+water ring vacuum unit |

Control method | PLC automatic control+touch screen operation | Canachieveremotemonitoringanddatatraceability(optional) |

Common Faults and Solutions

During operation, Rotating vacuum filter may encounter malfunctions due to material characteristics, improper operation, or wear and tear. Prompt troubleshooting can effectively prevent losses caused by downtime. Below are common faults and their solutions.

Common Faults | Possible reasons | Solution |

Sudden decrease in filtering speed | 1. Filter cloth blockage | 1. Clean the filter cloth and replace it if necessary |

The moisture content of the filter cake is too high | 1. Insufficient vacuum degree in the drying area | 1. Increase vacuum level |

Difficulty in removing filter cake | 1. The gap between the scraper and the filter drum is too large | 1. Fine tune the gap between the scraper blades |

Frequent breakage of filter cloth | 1. The sharpness of the scraper is too high or the gap is too small | 1. Polish the edge of the scraper and increase the gap between the scrapers |

Abnormal vibration of equipment | 1. Unbalanced filter drum | 1. Adjust the feeding amount to ensure uniform thickness of the filter cake |

Large fluctuations in vacuum degree | 1. Distribution head seal worn out | 1.Replacethesealingringofthedistributionhead2.Adjustthefeedingspeedandstabilizetheliquidlevel3.Coolingvacuumpumpworkingfluid |

Operation, maintenance and after-sales service of rotary vacuum filter

We alleviate customer concerns by focusing on operational convenience and after-sales support.

Simple Operation: Equipped with a touchscreen interface featuring intuitive cross-sectional displays, employees can operate independently after just 1-2 days of training. The system includes fault diagnosis capabilities for rapid issue identification, minimizing downtime.

Low Maintenance Costs: Core components utilize premium materials, ensuring a drum lifespan of 8-10 years. Bearings require maintenance every 1-2 years, while filter cloths can be replaced based on usage patterns.

Comprehensive After-Sales Service System:

Pre-sales: Free material testing and process planning provided.

During sales: Complimentary equipment installation guidance, staff training, and commissioning to ensure rapid production start-up.

Post-sales: Guaranteed 24-hour response to malfunctions; lifetime technical consultation and spare parts supply provided.

Hot Tags: