The horizontal vacuum filter utilizes vacuum negative pressure to drive solid-liquid separation, enabling continuous operations including filtration, washing, drying, and filter cloth regeneration. This equipment features high filtration efficiency, large production capacity, excellent washing performance, flexible operation, and low maintenance costs.

Vacuum Belt Assembly

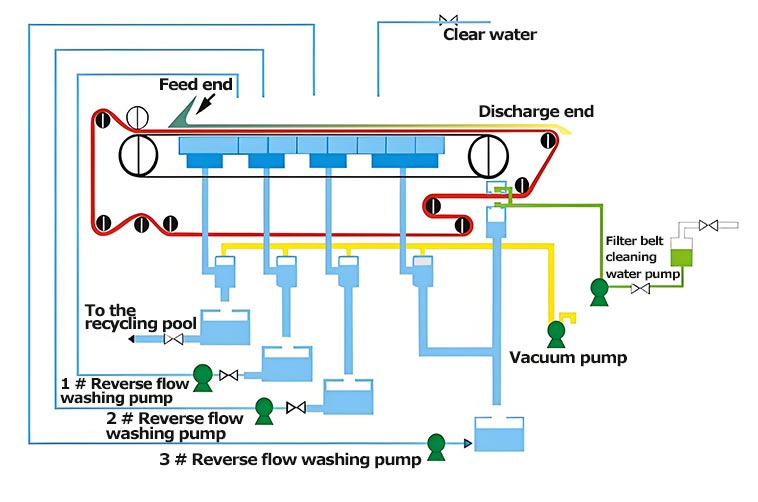

The vacuum belt assembly is a critical component of horizontal vacuum filters, primarily consisting of a rubber filter belt, vacuum chamber, drive rollers, and conveyor belt support platform. The rubber filter belt serves as the primary filtration medium, with its performance directly impacting filtration efficiency and equipment operational effectiveness. The vacuum chamber maintains sliding contact with the filter belt, forming a vacuum adsorption zone through a water seal.

Working Principle

During operation, the motor first delivers stable power through a reduction gearbox, continuously driving the circular filter bag. The filter cloth, pre-laid on the filter belt surface, moves synchronously with the belt, preparing for subsequent solid-liquid separation.

When the circular filter belt maintains sliding contact with the vacuum chamber, connecting the chamber to an external vacuum system creates a stable vacuum adsorption zone on the belt surface—the key condition for achieving separation.

Subsequently, the slurry to be processed is evenly distributed onto the filter cloth via a dedicated device. Upon entering the vacuum adsorption zone, the liquid component of the slurry permeates the filter cloth under negative pressure and flows into the vacuum chamber through transverse channels on the filter belt surface. Simultaneously, solid particles in the slurry are intercepted by the filter cloth, gradually accumulating to form a filter cake.

As the filter belt continues to move, the formed filter cake sequentially enters the equipment's washing zone and drying zone for optimized processing. In the final stage of the entire process, the filter cloth separates from the circular filter belt. Assisted by the discharge roller, the filter cake is smoothly unloaded. The filter cloth, cleaned to remove residual impurities, returns to the surface of the filter belt to initiate the next filtration cycle, ensuring continuous operation of the equipment.

Features

Leveraging “continuous vacuum adsorption + modular design,” the equipment delivers significant advantages in solid-liquid separation:

1. High separation efficiency with stable throughput

Maintaining continuous negative pressure in the vacuum chamber enables rapid filtrate extraction. Combined with uniform filter belt operation, it achieves uninterrupted “feed-separation-discharge” continuous processing. Compared to traditional equipment like plate-and-frame filter presses, it handles larger volumes with stable cake moisture content (15%-30%), reducing downstream costs and supporting large-scale production.

2. High Cake Purity and Superior Washing Performance

A dedicated washing zone employs sprayed cleaning solution that penetrates the cake thoroughly via vacuum pressure, achieving “displacement washing” with efficiency exceeding 99.8% in certain scenarios. Multi-stage washing further reduces impurities, meeting high-purity industry requirements.

3. User-Friendly Operation and High Automation

Driven by motors + reduction gearboxes, the PLC control system dynamically adjusts belt speed, vacuum pressure, and other parameters in real time, minimizing manual intervention. Filter cloths undergo automatic cleaning and regeneration, eliminating frequent disassembly, reducing labor intensity, and ensuring stable filtration performance.

4. Wide Application Range

Adaptable to high-viscosity, fine-particle, corrosive, and easily contaminated materials by adjusting filter cloth material and vacuum pressure. The “thin-layer filtration” design efficiently handles difficult-to-filter substances, preventing downtime issues common in traditional equipment.

5. Low Maintenance Costs

Core components utilize wear-resistant and corrosion-resistant materials. Modular design facilitates individual component servicing, minimizing downtime. Reusable filter cloths reduce consumable replacements, with a service life of 8-10 years under proper maintenance.

Specification Parameters Table

Parameter name | Conventional range/specifications |

Filtration area | Small:2-60㎡ Large: 60-120㎡ Customized:≤150㎡ |

Filter belt width | 500mm-3200mm, Commonly used 1000mm、2000mm、3000mm |

Filter belt material | Corrosion resistant rubber (normal working conditions), fluororubber (strong corrosion), food grade rubber (food industry) |

Filter belt speed | 0.5-5m/min |

Equipment length | Small: 4-10m Large: 15-35m |

Device width | Filter bandwidth 100-300mm |

Equipment height | 1.5-3m |

Equipment weight | 2-60㎡models:3.0-25.6t Over 60㎡:30-80t |

Degree of vacuum | -0.06MPa to - 0.095MPa |

Vacuum pump power | Small: 5.5-15kW Large: 37-75kW |

Processing capacity (slurry volume) | 5-200m³/h |

Processing capacity (dry material output) | 0.5-50t/h |

Moisture content of filter cake | 15%-30% |

Washing water usage | 0.5-3m³/h |

Washing efficiency | Conventional ≥ 95%, fine working conditions (chemical purification) ≥ 99.8% |

Power supply voltage | 380V (three-phase five wire system); Large equipment requires customized high-voltage power supply (such as 6kV) |

Operating Temperature | -10℃-40℃ |

Operating Humidity | ≤ 90% (no condensed water) |

Corrosion resistance level | Ordinary models: resistant to weak corrosion; Customized model (316L stainless steel): resistant to strong corrosion |

Head of feed pump | ≥ 10m |

Volume of filtrate tank | ≥10minutefiltrateproductionofequipment |

Applications of Horizontal Vacuum Filters

Leveraging its advantages of continuous separation, efficient washing, and adaptability to diverse materials, this equipment serves core scenarios across multiple industries, specifically as follows

Environmental Treatment Sector

· Industrial wastewater sludge dewatering: Reduces sludge moisture content from 95%+ to 25%-30%, achieving volume reduction and cost savings;

· Flue gas desulfurization gypsum processing: Separates gypsum slurry into dry gypsum with 15%-20% moisture content for building materials;

· Municipal sludge drying: Automated treatment of urban sludge prevents pollution and facilitates subsequent disposal.

Mining and Metallurgy Sector

· Mineral concentrate processing: Wash + dewater to remove chemicals, reducing moisture content to 20%-25% and enhancing smelting efficiency;

· Tailings dry stacking: Dewatering tailings slurry from 5%-15% solids content to 25%-30%, reducing tailings pond costs and risks;

· Smelting slag recovery: Separating leaching residues and anode sludge to recover residual metals, enabling dry disposal.

Chemical and Pharmaceutical Sector

· Chemical product purification: Multi-stage washing removes impurities, achieving ≥98% purity in filter cakes;

· Solvent recovery: Separate solvent-containing slurries to recover ethanol, acetone, etc., for recycling;

· Pharmaceutical intermediate separation: Meet GMP standards using 316L stainless steel + food-grade filter cloth for sterile automated separation.

Food Processing Sector

· Starch/sugar processing: Dehydrate starch slurry to 25%-30%, separate sugar syrup from mother liquor to enhance purity;

· Fruit and Vegetable Processing: Recover and dehydrate fruit pulp for animal feed or dietary fiber applications;

· Dairy Processing Support: Treat whey protein residue and cheese filter cake to meet sanitary standards.

Building Materials and Pulp & Paper Industry

· Building Material Pre-treatment: Dehydrate raw materials for kiln reprocessing or molding;

· Paper Mill Solid Waste Recovery: Dehydrate white mud for use as filler or building material;

· New building materials: Dewater fly ash and slag for wall material production.

Other Specialized Applications

· New energy materials: Process lithium battery slurries (e.g., lithium iron phosphate) to control moisture content and purity;

· Seawater desalination: Separate crystallized salts from brine for dewatering and recovery;

· Coatings/pigments: Separate slurries to remove solvents and enhance product purity.

Hot Tags: